Robot Palletising of seed bags

AGF Seeds is a family owned business operating in regional western Victoria providing quality, trusted seed!

Primary reasons for sourcing a robot stacker were to increase production rates and lower handling strains on workers. Implementing a palletising robot into production increased output and eliminated the OHS risks associated with repetitive bag stacking.

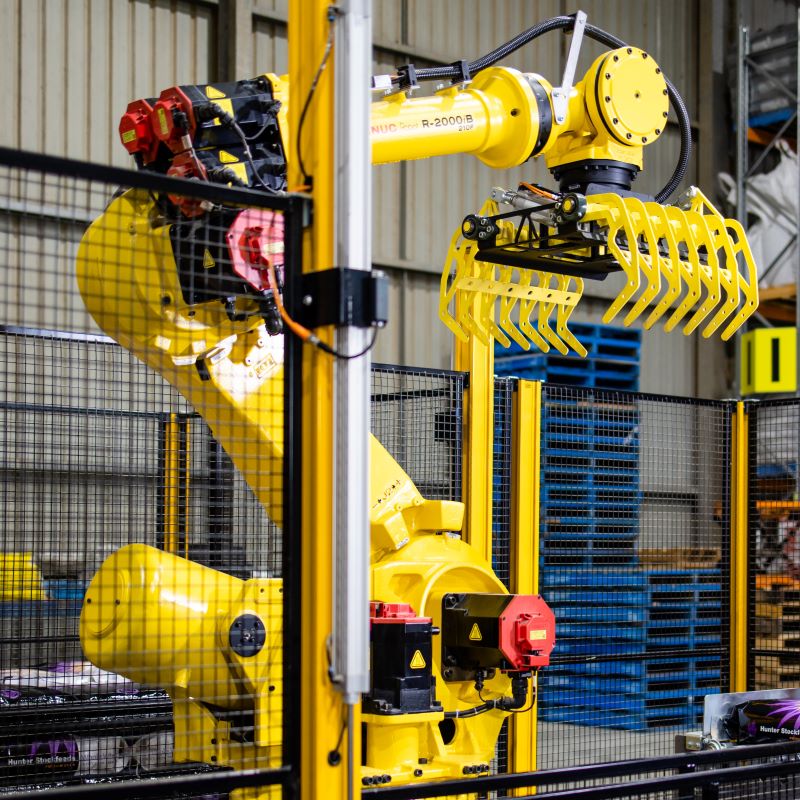

The feed bag palletising system has been designed to accommodate various sized bags and pallet configurations, and utilises a light weight robotic bag gripper.

The robot is generally working at 50% output when stacking bags at 4 per minute. When required, the robot can restack a damaged pallet in around 5 minutes.

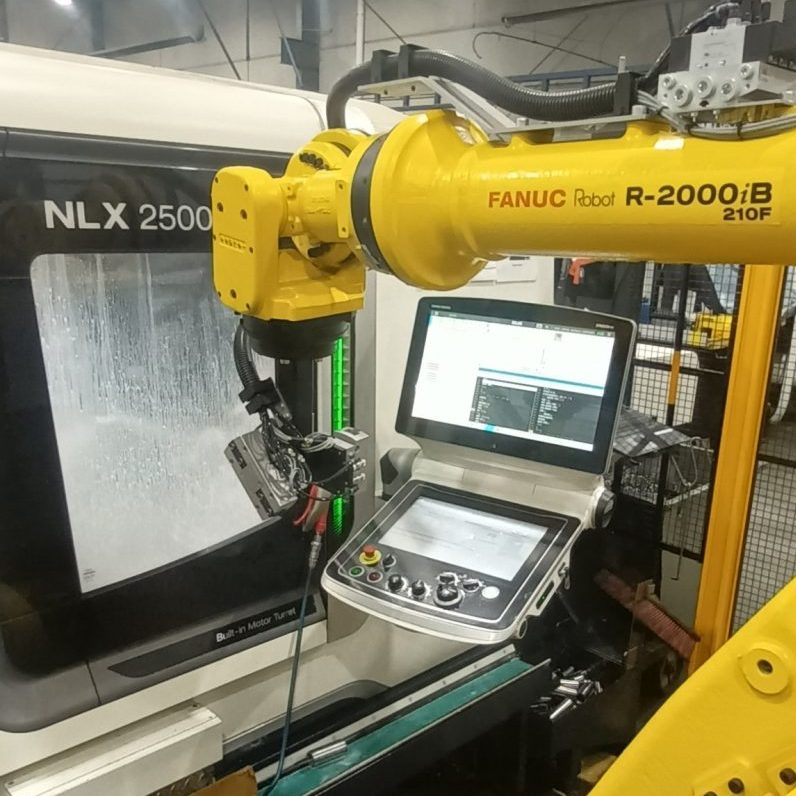

The robot palletiser operates with a HMI for simple ease of use and product selection. Product mixes are saved as recipes and are called up or altered easily.

AGF Seeds worked with local engineering company Jastech to supply the infeed conveyor system and robot fencing.

The Fanuc R2000 210F robot is perfect for palletising applications due to its large working envelope, high payload, and adequate speed.

If you are also looking for an intelligent cost effective automated solution to stack bags or boxes, then Automation Solutions has a solution for you.

Contact us today!